Fibres & Fabrics

7 Biofabric Producers You Need to Know About

Biofabrication - Definition

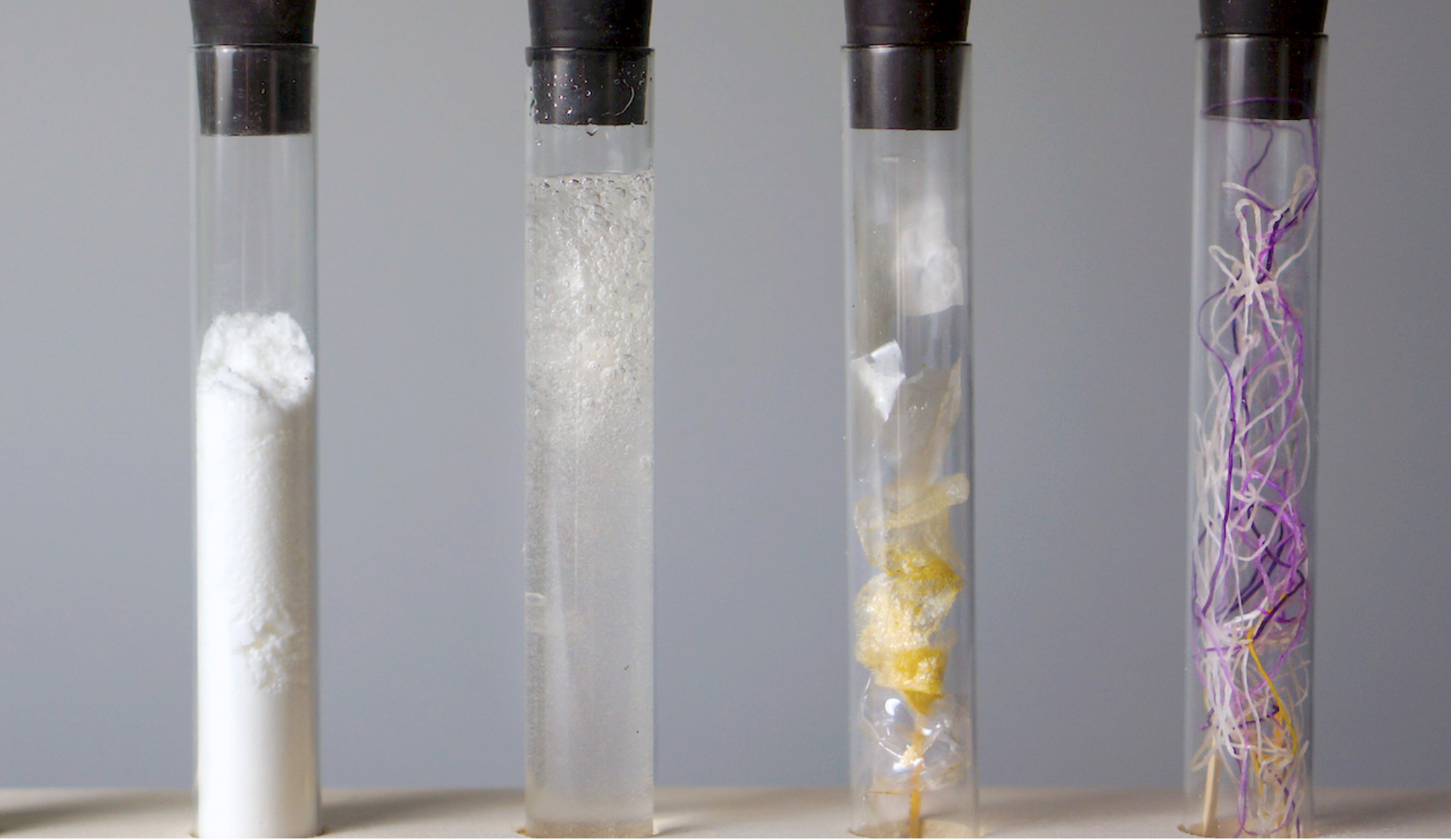

Rather than creating materials from extracting raw materials from oil, animals and plants, biofabrication is a process of growing materials using living microorganisms.

Biofabrication is actually a very old process. Humans have been harnessing the power of microorganisms for thousands of years - think bread, cheese and beer, as well as medicines such as insulin.

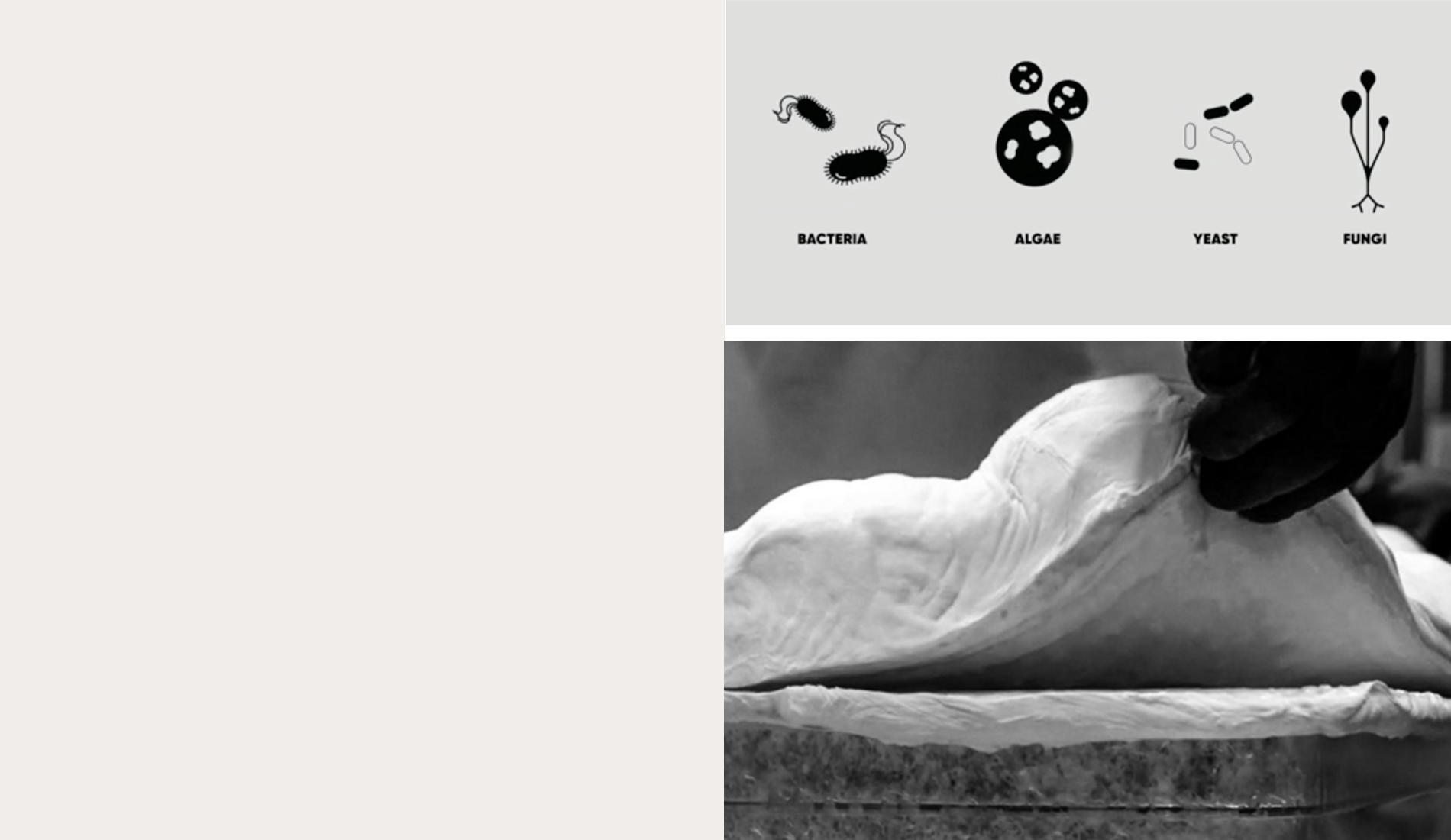

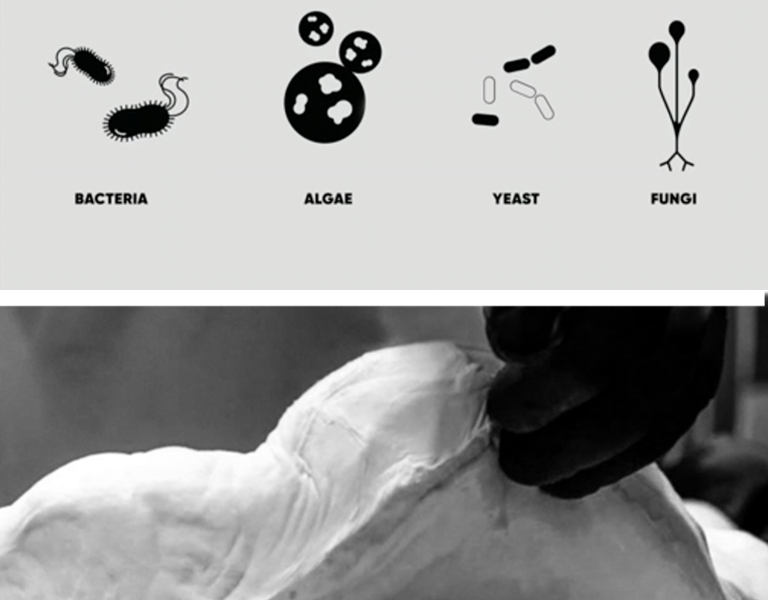

Today’s new biofabric mills are not factories but laboratories of living cells: bacteria, fungi, algae and yeast.

Watch this video by Biofabricate to learn more.

Biofabrication - Definition

Rather than creating materials from extracting raw materials from oil, animals and plants, biofabrication is a process of growing materials using living microorganisms.

Biofabrication is actually a very old process. Humans have been harnessing the power of microorganisms for thousands of years - think bread, cheese and beer, as well as medicines such as insulin.

Today’s new biofabric mills are not factories but laboratories of living cells: bacteria, fungi, algae and yeast.

Watch this video by Biofabricate to learn more.

Biofabrication - Benefits

The key sustainable benefits of biofabricated materials are: their ability to be grown into pre-determined structures thus eliminating waste, the speed with which they can be created (in a matter of days), and the elimination of traditional textile inputs such as fertilisers, pesticides, water, oil and chemicals as well as the use of arable land. They are also biodegradable.

For designers, they offer exciting creative possibilities. The DNA structures of the microorganisms can be altered to create specific textures and technical properties.

Biofabrication - Benefits

The key sustainable benefits of biofabricated materials are: their ability to be grown into pre-determined structures thus eliminating waste, the speed with which they can be created (in a matter of days), and the elimination of traditional textile inputs such as fertilisers, pesticides, water, oil and chemicals as well as the use of arable land. They are also biodegradable.

For designers, they offer exciting creative possibilities. The DNA structures of the microorganisms can be altered to create specific textures and technical properties.

Ecovative

New York based Ecovative’s MycoFlex™ is a biofabric made from mycelium, a material derived from the root structures of mushrooms. It can be used for a variety of applications including as a leather and faux leather alternative.

Ecovative, one of the pioneers of biofabrication, has a non-exclusive partnership with Bolt Threads, and are actively seeking partners to explore opportunities to use their technology.

Connect with Ecovative on CO

Image: The Stella McCartney Falabella bag made from Mylo leather by Bolt Threads

Ecovative

New York based Ecovative’s MycoFlex™ is a biofabric made from mycelium, a material derived from the root structures of mushrooms. It can be used for a variety of applications including as a leather and faux leather alternative.

Ecovative, one of the pioneers of biofabrication, has a non-exclusive partnership with Bolt Threads, and are actively seeking partners to explore opportunities to use their technology.

Connect with Ecovative on CO

Image: The Stella McCartney Falabella bag made from Mylo leather by Bolt Threads

Algalife

Global Change Award 2018 Winner, Algalife, is a German-Israeli start-up developing biofabrics and dyes made from algae. In addition to being zero waste, economic and fast to grow, biodegradable and from a renewable resource, it is claimed that the algae releases nourishing proteins, vitamins and anti-inflammatory and antioxidant elements to the skin when worn.

Watch the video by Algalife to learn more.

Connect with Algalife on CO

Algalife

Global Change Award 2018 Winner, Algalife, is a German-Israeli start-up developing biofabrics and dyes made from algae. In addition to being zero waste, economic and fast to grow, biodegradable and from a renewable resource, it is claimed that the algae releases nourishing proteins, vitamins and anti-inflammatory and antioxidant elements to the skin when worn.

Watch the video by Algalife to learn more.

Connect with Algalife on CO

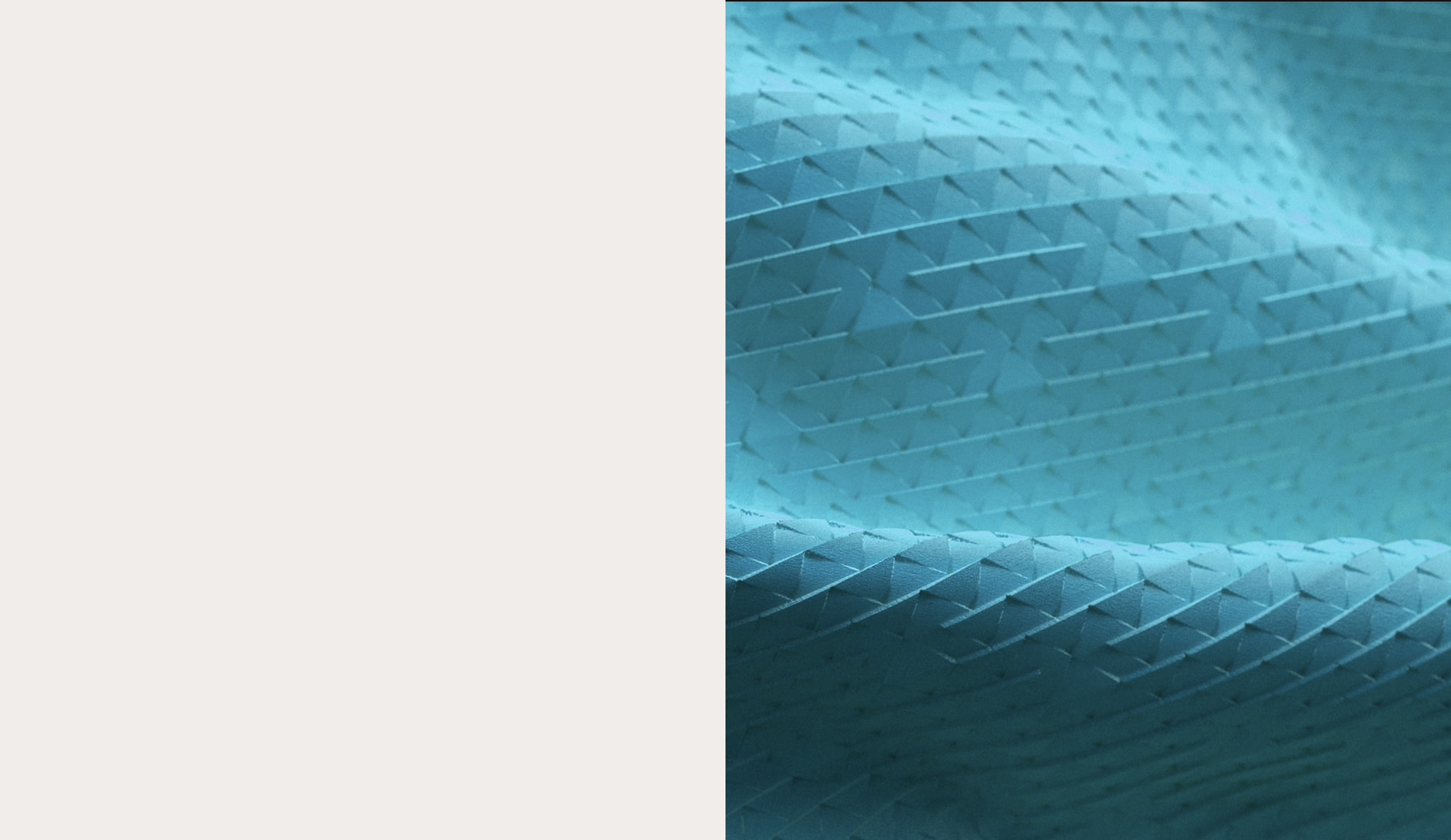

Modern Meadow

Zoa, by Modern Meadow is another biofabricated vegan leather. Made using collagen protein derived from yeast, the DNA of the living cells can be modified to create a customisable look and finish to the material. New properties such as patterning and lighter-weight options and a variety of textures and colours will also be available.

While still in the development stage Modern Meadows has already raised $53.5 million in funding from investors and has partnered with leading designers to create prototypes.

Watch this video to find out more.

Connect with Modern Meadow on CO

Modern Meadow

Zoa, by Modern Meadow is another biofabricated vegan leather. Made using collagen protein derived from yeast, the DNA of the living cells can be modified to create a customisable look and finish to the material. New properties such as patterning and lighter-weight options and a variety of textures and colours will also be available.

While still in the development stage Modern Meadows has already raised $53.5 million in funding from investors and has partnered with leading designers to create prototypes.

Watch this video to find out more.

Connect with Modern Meadow on CO

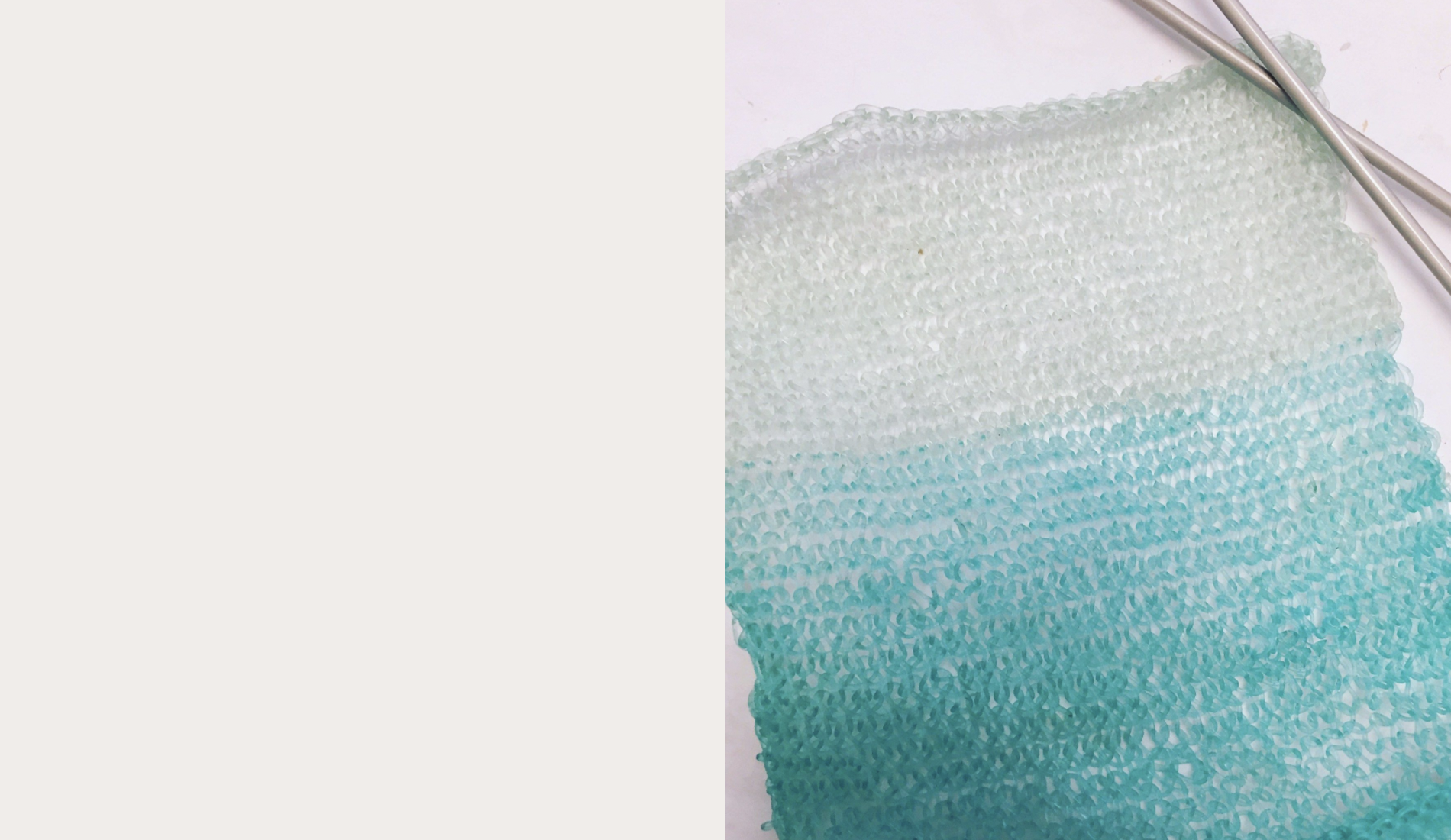

Algiknit

LVMH Innovation Award Finalist 2018, AlgiKnit Inc. is a US company creating yarns from Kelp. The benefit of using kelp, as with all these biofabrications, is that it is extremely fast growing and doesn’t require harmful chemicals or fertilisers, it doesn’t require arable land to grow and has the added benefit of sequestering carbon. While still in development, Algiknit, hope to scale up their yarn production to produce fibre for the apparel and footwear industries.

Watch this video to learn more about Algiknit.

Connect with Algiknit on CO

Algiknit

LVMH Innovation Award Finalist 2018, AlgiKnit Inc. is a US company creating yarns from Kelp. The benefit of using kelp, as with all these biofabrications, is that it is extremely fast growing and doesn’t require harmful chemicals or fertilisers, it doesn’t require arable land to grow and has the added benefit of sequestering carbon. While still in development, Algiknit, hope to scale up their yarn production to produce fibre for the apparel and footwear industries.

Watch this video to learn more about Algiknit.

Connect with Algiknit on CO

Spiber

Japanese company Spiber makes a protein fibre called Brewed Protein, based on the DNA used to produce spider silk.

Incredibly strong yet lightweight and flexible, it has all the ingredients which make it ideal for sportswear and technical applications.

The protein can be processed into anything from delicate filament fibres to leather and fur alternatives as well as tortoiseshell and horn imitations. Commercial production is due to begin in 2021.

Watch this video to find out more about Spiber.

Connect with Spiber on CO

Spiber

Japanese company Spiber makes a protein fibre called Brewed Protein, based on the DNA used to produce spider silk.

Incredibly strong yet lightweight and flexible, it has all the ingredients which make it ideal for sportswear and technical applications.

The protein can be processed into anything from delicate filament fibres to leather and fur alternatives as well as tortoiseshell and horn imitations. Commercial production is due to begin in 2021.

Watch this video to find out more about Spiber.

Connect with Spiber on CO

Bolt Threads

Californian based Bolt Threads produces Mylo - made from mycelium, an alternative to real and faux leather. They also make Microsilk, Bolt Threads’s version of spider silk (see Spiber). The sugar used to feed the microorganisms is made from corn (worth noting however that in the US most corn is genetically modified).

In 2017 they launched their first commercially available product - a tie made from Microsilk.

Watch this video to learn more about Bolt Threads.

Connect with Bolt Threads on CO

Bolt Threads

Californian based Bolt Threads produces Mylo - made from mycelium, an alternative to real and faux leather. They also make Microsilk, Bolt Threads’s version of spider silk (see Spiber). The sugar used to feed the microorganisms is made from corn (worth noting however that in the US most corn is genetically modified).

In 2017 they launched their first commercially available product - a tie made from Microsilk.

Watch this video to learn more about Bolt Threads.

Connect with Bolt Threads on CO

Le Qara

Global Change Award Winner of 2019, Le Qara is another vegan leather alternative grown in a lab. Derived from microorganisms from flowers and fruits, it is breathable and biodegradable and can be made to mimic any type of leather texture and thickness.

Residues from the processing can also be used as a liquid compost, making it zero waste.

Watch the video by Le Qara to learn more.

Connect with Le Qara on CO

Le Qara

Global Change Award Winner of 2019, Le Qara is another vegan leather alternative grown in a lab. Derived from microorganisms from flowers and fruits, it is breathable and biodegradable and can be made to mimic any type of leather texture and thickness.

Residues from the processing can also be used as a liquid compost, making it zero waste.

Watch the video by Le Qara to learn more.

Connect with Le Qara on CO

First published 09.04.2020 - Updated 09.12.2021

Related Reading

Sign up to connect with 50,000+ other sustainability-minded professionals and access over 300 pieces of actionable intelligence.

Common Objective is a global sourcing and information network that enables you to succeed in sustainable fashion business.