Fibres & Fabrics

Fabric Switch: Sourcing Sustainable Cotton

Introduction

From jersey to woven, t-shirts to tailoring, cotton remains the most used natural fibre - making up around 24% of all fibre used in apparel production.

Prized for its softness, strength, breathability, absorbency and washability, cotton also blends brilliantly with with other fibres.

Read CO’s full report - Cotton and Sustainable Cotton: Key World Commodity - for more details on cotton production and its impact.

Introduction

From jersey to woven, t-shirts to tailoring, cotton remains the most used natural fibre - making up around 24% of all fibre used in apparel production.

Prized for its softness, strength, breathability, absorbency and washability, cotton also blends brilliantly with with other fibres.

Read CO’s full report - Cotton and Sustainable Cotton: Key World Commodity - for more details on cotton production and its impact.

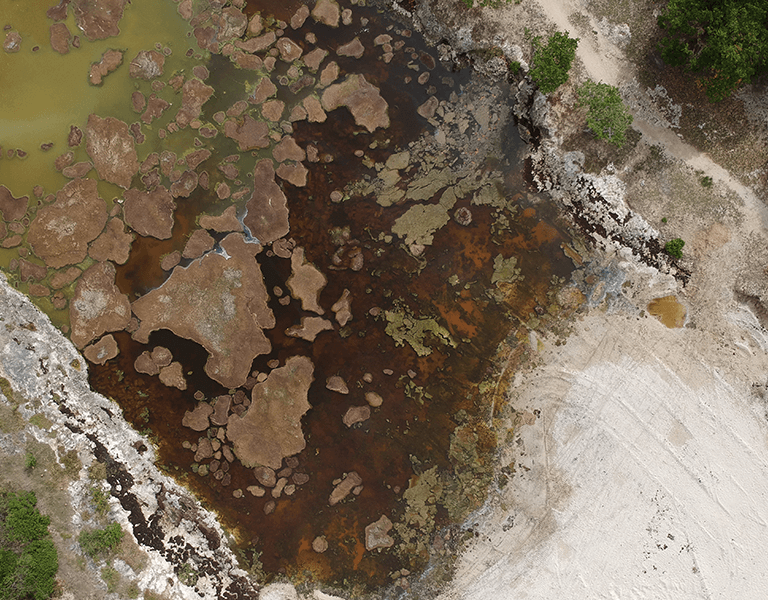

Environmental Impact

Although a natural fibre, conventional cotton production and processing have two major environmental impacts:

- Water - it relies on wasteful flood irrigation

- Pollution & chemicals - it uses high levels of pesticides, fertilisers and chemicals that affect human health and pollute local eco-systems

Read more in the CO Cotton Briefing

Environmental Impact

Although a natural fibre, conventional cotton production and processing have two major environmental impacts:

- Water - it relies on wasteful flood irrigation

- Pollution & chemicals - it uses high levels of pesticides, fertilisers and chemicals that affect human health and pollute local eco-systems

Read more in the CO Cotton Briefing

Human Impact

Smallholder cotton farmers in developing countries (over 100 million households) are at the sharp end of injustices in global trade.

In particular, subsidies for cotton farmers in some countries, particularly the US, create a market with artificially low prices that small-scale farmers are unable to compete in.

There have also been reports of large scale use of forced child labour growing GM cotton seeds in India.

Human Impact

Smallholder cotton farmers in developing countries (over 100 million households) are at the sharp end of injustices in global trade.

In particular, subsidies for cotton farmers in some countries, particularly the US, create a market with artificially low prices that small-scale farmers are unable to compete in.

There have also been reports of large scale use of forced child labour growing GM cotton seeds in India.

What are the solutions?

There are three key ways that fashion businesses can source better cotton. We'll look at both of these in this guide.

1. Buy better grown cotton

Look for Fairtrade, GOTS, Cotton Made in Africa, REEL and the Better Cotton Initiative.

2. Reuse the cotton that already exists

Innovative circular systems that reduce the need for virgin fibres.

3. Source traceable cotton

Avoid fraudulent 'sustainable' cotton, know where your fibre comes from and in doing so support farmers.

What are the solutions?

There are three key ways that fashion businesses can source better cotton. We'll look at both of these in this guide.

1. Buy better grown cotton

Look for Fairtrade, GOTS, Cotton Made in Africa, REEL and the Better Cotton Initiative.

2. Reuse the cotton that already exists

Innovative circular systems that reduce the need for virgin fibres.

3. Source traceable cotton

Avoid fraudulent 'sustainable' cotton, know where your fibre comes from and in doing so support farmers.

Switch to organic cotton

Organic certified cotton has strict criteria for the use of pesticides and insecticides and farm management.

Textile Exchange has released its 2021 Organic Cotton Market Report revealing that the 2019/20 season saw the largest volume of organic cotton fibre harvested globally to date.

What you can do:

- Ask your current fabric and fibre suppliers if they can source organic cotton for you

- Search the Global Organic Textile Standard database for fabrics that meet your product requirements

Image: Lanius, using GOTS-certified cotton

Switch to organic cotton

Organic certified cotton has strict criteria for the use of pesticides and insecticides and farm management.

Textile Exchange has released its 2021 Organic Cotton Market Report revealing that the 2019/20 season saw the largest volume of organic cotton fibre harvested globally to date.

What you can do:

- Ask your current fabric and fibre suppliers if they can source organic cotton for you

- Search the Global Organic Textile Standard database for fabrics that meet your product requirements

Image: Lanius, using GOTS-certified cotton

Regenerative Agriculture Cotton

Regenerative cotton is grown on farms that use holistic farming practices such as no-tilling and crop rotation. These practices generate multiple benefits including improving soil health, sequestering carbon and restoring biodiversity.

What you can do:

- Connect with Fibershed to find out more about climate beneficial cotton grown in Northern California.

- Get in touch with Oshadi Collective a vertical supplier that operates a 50-acre regenerative cotton farm in India.

Regenerative Agriculture Cotton

Regenerative cotton is grown on farms that use holistic farming practices such as no-tilling and crop rotation. These practices generate multiple benefits including improving soil health, sequestering carbon and restoring biodiversity.

What you can do:

- Connect with Fibershed to find out more about climate beneficial cotton grown in Northern California.

- Get in touch with Oshadi Collective a vertical supplier that operates a 50-acre regenerative cotton farm in India.

Cotton in transition

Cotton in transition refers to when conventional farmers switch to organic cotton farming but have not yet obtained certifications.

What you can do:

- Ask your mill about transitional cotton - help farmers who are working towards organic certification and source sustainable cotton at a more affordable price by purchasing transitional cotton.

Cotton in transition

Cotton in transition refers to when conventional farmers switch to organic cotton farming but have not yet obtained certifications.

What you can do:

- Ask your mill about transitional cotton - help farmers who are working towards organic certification and source sustainable cotton at a more affordable price by purchasing transitional cotton.

Switch to Fairtrade cotton

Fairtrade certified cotton guarantees farmers a fair price plus pays a premium for social development. It also has strong environmental criteria.

- Ask your current fabric suppliers if they can source Fairtrade cotton for you

- Search the FLO-Cert database (filter by cotton) to find mills and suppliers

- Connect with Fairtrade’s Cotton Product Manager who can help guide you as to the best way to switch

Images from top: Fairtrade, Arthur & Henry

Switch to Fairtrade cotton

Fairtrade certified cotton guarantees farmers a fair price plus pays a premium for social development. It also has strong environmental criteria.

- Ask your current fabric suppliers if they can source Fairtrade cotton for you

- Search the FLO-Cert database (filter by cotton) to find mills and suppliers

- Connect with Fairtrade’s Cotton Product Manager who can help guide you as to the best way to switch

Images from top: Fairtrade, Arthur & Henry

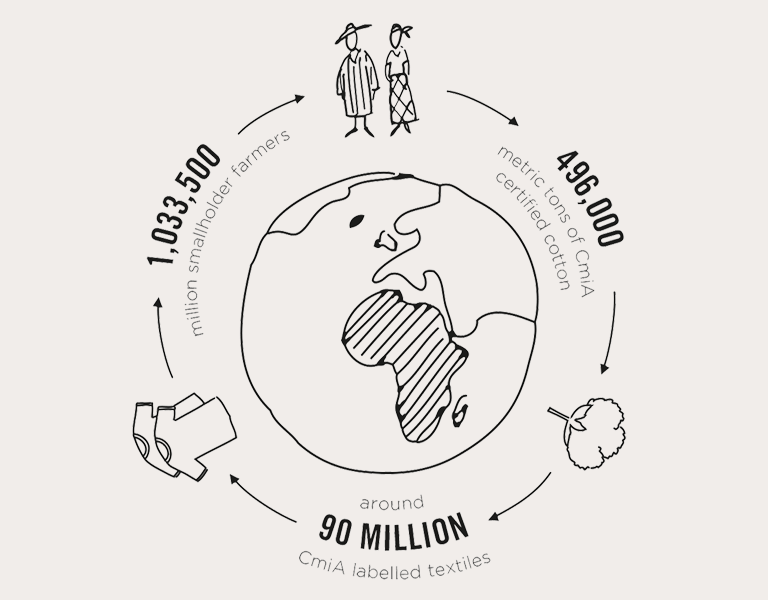

Cotton made in Africa

Sub-Saharan Africa is the fifth largest cotton exporter in the world, however the 20 million people directly or indirectly living off the cotton industry have been unable to make full use of this potential to alleviate poverty.

Cotton made in Africa (CmiA) supports African smallholder cotton farmers to improve their cultivation and thus their yields, creating a more stable cotton industry.

The benefit for buyers working with CmiA is both a more sustainable, transparent supply chain, as well as cost-efficiency. Become a CmiA partner to incorporate African cotton into your collections.

Cotton made in Africa

Sub-Saharan Africa is the fifth largest cotton exporter in the world, however the 20 million people directly or indirectly living off the cotton industry have been unable to make full use of this potential to alleviate poverty.

Cotton made in Africa (CmiA) supports African smallholder cotton farmers to improve their cultivation and thus their yields, creating a more stable cotton industry.

The benefit for buyers working with CmiA is both a more sustainable, transparent supply chain, as well as cost-efficiency. Become a CmiA partner to incorporate African cotton into your collections.

REEL from Cotton Connect

CottonConnect helps brands, particularly larger brands, improve their cotton supply chains by providing capacity-building on the ground with cotton farmers.

The REEL (standing for 'Responsible Environment, Enhanced Livelihoods') Cotton Programme is a three year agricultural training course that promotes more sustainable cotton farming and better business practices.

Primark has been working with CottonConnect since 2013 and based its own sustainable cotton programme on REEL.

REEL from Cotton Connect

CottonConnect helps brands, particularly larger brands, improve their cotton supply chains by providing capacity-building on the ground with cotton farmers.

The REEL (standing for 'Responsible Environment, Enhanced Livelihoods') Cotton Programme is a three year agricultural training course that promotes more sustainable cotton farming and better business practices.

Primark has been working with CottonConnect since 2013 and based its own sustainable cotton programme on REEL.

Better Cotton Initiative

The Better Cotton Initiative (BCI) works with farmers to have a holistic approach to more sustainable cotton production. It has come under fire for its cautious approach to sustainability that only addresses the beginning of the supply chain as well as more recently for sourcing cotton from Xinjiang province in China, an area known for its use of forced labour. We have included it here as it is a standard used by many retail brands and continues to dominate the 'more sustainable' cotton market.

What you can do:

- Ask your fabric supplier about BCI cotton

- Contact BCI to find out more about incorporating it into your production

Better Cotton Initiative

The Better Cotton Initiative (BCI) works with farmers to have a holistic approach to more sustainable cotton production. It has come under fire for its cautious approach to sustainability that only addresses the beginning of the supply chain as well as more recently for sourcing cotton from Xinjiang province in China, an area known for its use of forced labour. We have included it here as it is a standard used by many retail brands and continues to dominate the 'more sustainable' cotton market.

What you can do:

- Ask your fabric supplier about BCI cotton

- Contact BCI to find out more about incorporating it into your production

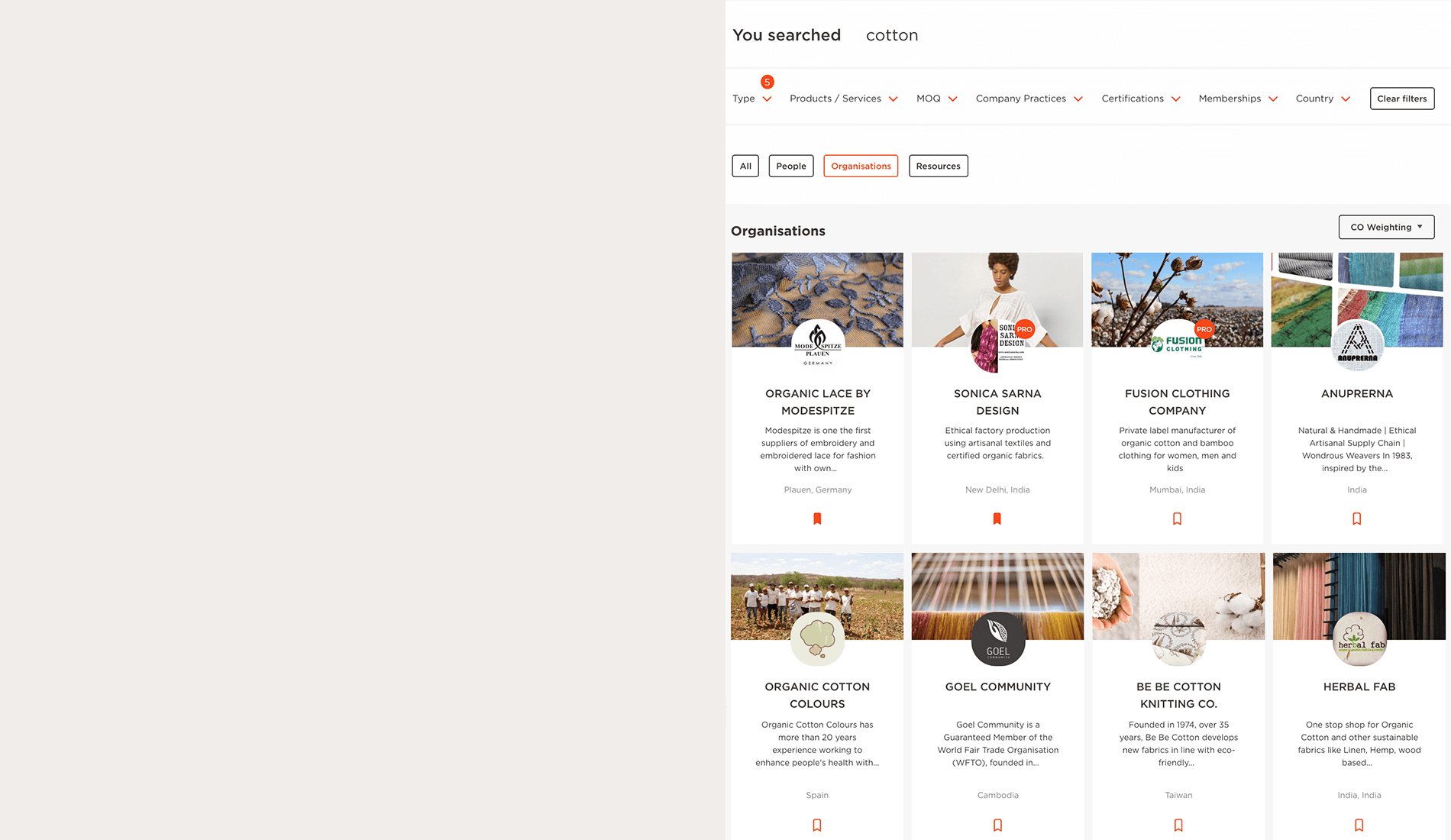

Cotton suppliers on CO

Click here to find businesses on CO that supply cotton fibres and fabrics.

Many of these are registered under the certifications or schemes mentioned in this guide.

You can also further refine the list to meet your product needs, eg by Minimum Order Quantity or Certification. Then connect with the individuals associated with the business.

Cotton suppliers on CO

Click here to find businesses on CO that supply cotton fibres and fabrics.

Many of these are registered under the certifications or schemes mentioned in this guide.

You can also further refine the list to meet your product needs, eg by Minimum Order Quantity or Certification. Then connect with the individuals associated with the business.

Taking African cotton to scale

Sourcing African cotton has historically been challenging because it often means shipping it around the world for processing, resulting in a fragmented and opaque supply chain.

In order to address this and promote African cotton more widely CO Partner, Plexus Cotton, have created an integrated supply chain from farm to fabric enabling brands and retailers to source sustainably at scale from Africa.

Taking African cotton to scale

Sourcing African cotton has historically been challenging because it often means shipping it around the world for processing, resulting in a fragmented and opaque supply chain.

In order to address this and promote African cotton more widely CO Partner, Plexus Cotton, have created an integrated supply chain from farm to fabric enabling brands and retailers to source sustainably at scale from Africa.

Innovative recycled cotton

Concerned about the amount of water used to grow even the most sustainable of cotton? Reuse may be the answer.

A growing number of pioneering mills are taking cotton waste, sorting by colour, and using it to make new yarn without the need for dyeing. Options include:

- Recover from Spain’s Hilaturas Ferre

- EcoTec from Italy’s Marchi & Fildi (pictured here in an Eileen Fisher garment)

- Pure Waste, a Finnish-Indian enterprise supplying fabric and garments

- Eco2Cotton in the USA

Innovative recycled cotton

Concerned about the amount of water used to grow even the most sustainable of cotton? Reuse may be the answer.

A growing number of pioneering mills are taking cotton waste, sorting by colour, and using it to make new yarn without the need for dyeing. Options include:

- Recover from Spain’s Hilaturas Ferre

- EcoTec from Italy’s Marchi & Fildi (pictured here in an Eileen Fisher garment)

- Pure Waste, a Finnish-Indian enterprise supplying fabric and garments

- Eco2Cotton in the USA

Turning cotton into new fibres

Is it cotton? Cotton waste can also be turned into ‘man-made’ fibres, giving the drape and functionality of a viscose rayon or lyocell.

Most recycled yarns come from pre-consumer waste (ie textile and garment manufacturing) but re:newcell’s technology means they can make fibre from previously worn clothes - the ones that normally end up in landfill.

Fibre pioneers Lenzing have used waste cotton in their new Refibra tencel lyocell (pictured here with Reformation).

Turning cotton into new fibres

Is it cotton? Cotton waste can also be turned into ‘man-made’ fibres, giving the drape and functionality of a viscose rayon or lyocell.

Most recycled yarns come from pre-consumer waste (ie textile and garment manufacturing) but re:newcell’s technology means they can make fibre from previously worn clothes - the ones that normally end up in landfill.

Fibre pioneers Lenzing have used waste cotton in their new Refibra tencel lyocell (pictured here with Reformation).

Natural colours

Naturally coloured cotton removes the need for dyeing with its consequent environmental impacts both in the amount of water needed and the potential pollution from dyestuffs entering waterways.

Three companies that offer this are Spanish-based Organic Cotton Colours, Brazilian company Natural Cotton Color and Peru's Naturtex.

Natural colours

Naturally coloured cotton removes the need for dyeing with its consequent environmental impacts both in the amount of water needed and the potential pollution from dyestuffs entering waterways.

Three companies that offer this are Spanish-based Organic Cotton Colours, Brazilian company Natural Cotton Color and Peru's Naturtex.

First published 03.11.2018 - Updated 13.12.2021

Related Reading

Sign up to connect with 50,000+ other sustainability-minded professionals and access over 300 pieces of actionable intelligence.

Common Objective is a global sourcing and information network that enables you to succeed in sustainable fashion business.